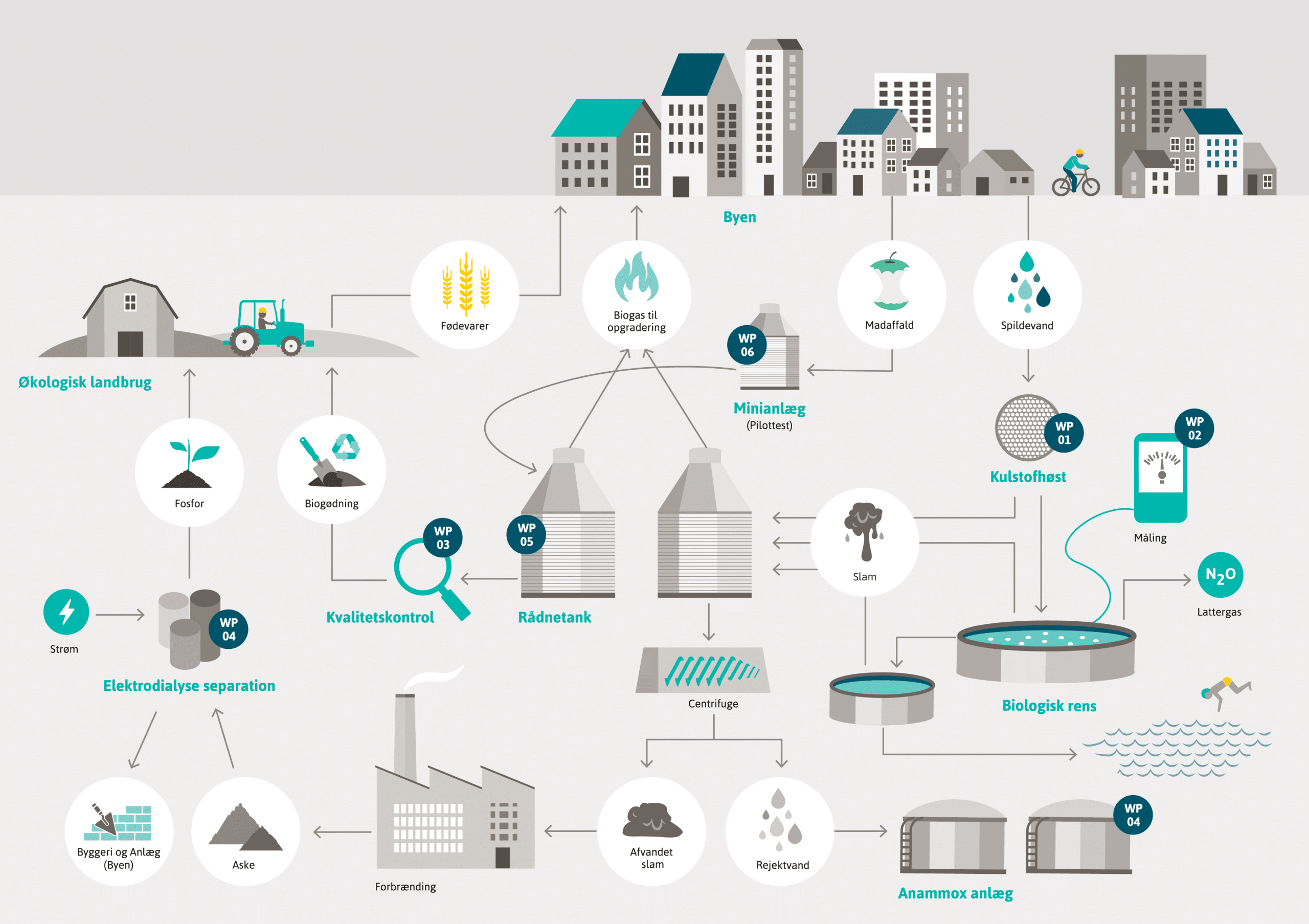

The main purpose of the lighthouse project was to transform a traditional wastewater treatment plant into a Water & Resource Recovery Plant, hence the name VARGA. In addition, the project has aimed to ensure that the resources in the city’s wastewater and waste are utilized even better than they are today and that more consideration is given to which resources should be harvested from the wastewater for the benefit of the city’s citizens.

Together with BIOFOS and the other partners, Envidan was granted just over DKK 19 million from the Ministry of the Environment under the MUDP program for the lighthouse project VARGA in 2017.

The project investigated essential parts of the circular economy, focusing on the utilization of carbon and nutrients in urban waste and wastewater for the production of biogas and organic food, respectively. The project sought to create synergies utilizing resources across the water, waste, and organic farming sectors. This has been met to a great extent.

The project has covered the following aspects

- Carbon harvesting and primary sludge concentration

- Phosphorus recovery from sludge ash

- Separate digestion of source-separated organic municipal waste (MSW) with biogas upgrading to biomethane

- Reduction of climate footprint from nitrous oxide emissions in particular

- Life Cycle Assessment (LCA)

- Economic impact calculations

The project has allowed the parties to delve into many aspects and the results speak for themselves.

“We need to change the entire mindset so that in the future we think of a wastewater treatment plant as a resource plant. The project has provided a unique opportunity for Denmark to emerge as a pioneering country where we both purify water and make the best possible use of the resources in wastewater”

The Road to the future treatment plant

After the project, it is now possible to say that the project has helped chalk out the forward-looking goals for the future treatment plant.

Instead of a conventional wastewater treatment plant, we need to look at wastewater treatment plants as resource plants that both treat wastewater and sustainably utilize resources. This takes into account both the environmental and economic conditions as well as the local infrastructure and industrial symbiosis.

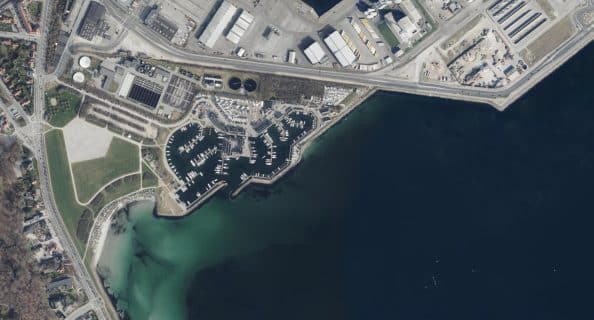

With the VARGA project, this was demonstrated at one of Denmark’s largest wastewater treatment plants, Avedøre (capacity of approx. 400,000 PE).

“As a development manager, it has been interesting to assess the potential of the VARGA lighthouse project, both as a reference plant, as a spin-off for new development projects, and concerning the development of new commercial products – it shows the importance of investing in research and development at Envidan.”

Results of the VARGA project

The VARGA project has provided results for an in-depth analysis of how a wastewater treatment plant can be transformed into a resource recovery facility that supports cities’ and society’s desire for a more circular economy.

In addition, the development project has contributed to knowledge about the potentials and challenges of transforming today’s treatment plants into the future of plants, focusing on recycling and better utilization of resources.

The benefits have spread like ripples and paved the way for many new development projects, innovation collaborations, and the start-up of a new company.

At the same time, VARGA, as a reference project, has contributed to an increased business potential for the commercial partners and has created joint dissemination activity with more than 50 presentations at conferences and 14 scientific articles.

Want to know more about the results?

Further down the page, we’ve gathered all the technical details of the results so you can learn even more.

From one development project to new projects and export opportunities

All parties benefit from this lighthouse project. This includes both the business potential of the commercial partners as well as newly derived development projects and collaborations.

Based on the VARGA project, new projects on resource utilization, minimization of nitrous oxide emissions, development of LCA tools, and, not least, a new startup company focusing on phosphorus recovery from the sludge axis have emerged.

VARGA is also used as a reference project and has been an important reference for us. new commercial projects and export of Danish-produced equipment and know-how.

“We see great export perspectives in the VARGA lighthouse project. Both within our consultancy services such as CO2-neutral treatment, circular economy, biogas upgrading, advanced online management of wastewater treatment plants, and deliveries of Salsnes filters for optimizing carbon harvesting and concentrating primary sludge”

Dive into the results

Phosphorus recovery from sludge ash

The ash from incinerating sludge from wastewater treatment plants typically contains 8-10% phosphorus. DTU Sustain has developed and tested a new electrodialytic method on a laboratory scale, using a new electrodialytic method. power and a membrane can recover up to 90% phosphorus from sludge.

A Danish startup company, Clean Matter ApS, is working on scaling up the process based on the promising results from the VARGA project. The residual sand consisting of silicon and iron oxides can be used as a filler material or as a replacement for cement in concrete and has great potential to increase the circular economy and reduce the carbon footprint of concrete.

Carbon harvesting

In the project, the pre-filtration of wastewater with belt filters for carbon harvesting has been tested in both pilot and full scale. The function is compared to the existing traditional clarifiers without pre-dewatering of primary sludge.

- A reduction of suspended solids (SS) of approximately 41% has been achieved. This is not significantly different from the SS reduction in the explanation tanks.

- In combination with a screw press, a concentration of primary sludge to 25-30% dry matter has been achieved with a suspended solids content in the reject water of approx. 1.5%.

- Operational savings by concentrating the primary sludge.

- Less need for heating digesters and increased biogas production results in potential operational savings.

- There have been challenges with the operation of the four prefilters, and unfortunately, the full potential was not realized until the plant had to be shut down due to rising energy costs.

Reduction of nitrous oxide emissions

Over 4 years, nitrous oxide measurements have been carried out, which have been used to calculate the baseline and to carry out tests of measures to reduce nitrous oxide emissions.

The results of the tests show a seasonal variation and that approximately 90% of the annual nitrous oxide emission at Avedøre WWTP occurs in the period from March to July. To reduce these emissions, various alternative solutions have been tested.

The greatest reduction in nitrous oxide is achieved by reducing the specific ammonium load through an increase in sludge concentration in the aeration tank combined with a superimposed ammonium-driven online aeration control.

A total nitrous oxide emission reduction of between 48-74% has been achieved, which translates to an average annual CO2 reduction of 10,400 tons of CO2 equivalents.

The cost of implementing the sensors and control strategy is estimated at 10-30 DKK/tonne ofCO2 removed,

If aCO2 tax of e.g. 700 DKK/tonneCO2 is introduced, the utilities will have a strong incentive to reduce nitrous oxide emissions with measures similar to those demonstrated in the VARGA project.

Separate digestion of KOD

With separate digestion of pulp from source-separated organic municipal solid waste (MSW) under mesophilic conditions at a pilot scale, an average biogas production of 370 Nm3 CH4/tVSin has been achieved. This is consistent with the theory and without the observation of inhibition.

Biological upgrading of biogas with hydrogen to biomethane using the microorganism Archea has been demonstrated in a pilot-scale biological filter.

Under thermophilic conditions, methane concentrations of 90% have been achieved and the process proved to be robust with very fast start-up after downtime.

Field trials have proven that the fertilizer value of the digestate is equivalent to pig slurry and a questionnaire survey among organic farmers has highlighted the need and willingness to pay.

Based on the nutrient value, the digestate, as a fertilizer product, is estimated to have a value of 35 to 80 DKK per ton.

Life cycle assessment and economic impact assessment

A life cycle assessment provides the opportunity to compare different environmental parameters and thus highlight the environmental impact of resource recovery and climate improvement initiatives tested in VARGA.

The results show that selected technological changes at the treatment plant have impacts far beyond supply in the energy and agricultural sectors, among others.

Significant environmental improvements have been demonstrated, but the benefits are based on key assumptions that are subject to uncertainty.

The results of the economic analyses show that the costs of transitioning to resource recovery generally exceed the economic benefits of the measures.

The work with LCA during the project period has, among other things, made it clearer and easier to make qualified choices between the options available for resource recovery.

Principles of resource recovery

Principles and perspectives for resource recovery with the production of products based on wastewater are elaborated in the report.

It is not resource recovery technologies that are limiting, but rather the quantity of resources and market value, societal acceptance of these products, regulatory aspects, as well as local infrastructure and opportunities for industrial symbiosis.

This can change significantly over time, for example with the introduction of carbon taxes.

Innovation is one of our key priorities at Envidan

That’s why we spend 20% of our profits on research and development every year.

Want to read more about Envidan’s development projects and the new research we provide in the water sector?