The technology is used in a simple and environmentally friendly way for several coastal and port protection projects.

Solmax Geotube® technology is used in a simple and environmentally friendly way for coastal and harbor protection. The product is a durable and proven solution for shoreline and sea protection and widely used in marine and hydraulic engineering, such as breakwaters, dikes and marine spill containment structures.

Once the Geotube® bag is in place, the solution provides years of sustained performance to protect coastlines, rebuild beaches or reclaim land.

Envidan is the only distributor in Denmark to offer the original Solmax Geotube®, which is a technology for several different coastal protection projects.

Cladding of banks

Coastal revetments can be eroded by wave action. Solmax Geotubes® can be used for a range of coastal erosion solutions that also improve access to public facilities and protect facilities and property

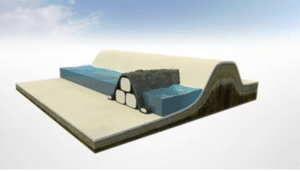

Dams

Dikes are often constructed to allow construction to take place in more suitable conditions. Solmax Geotubes® are widely used for this purpose, either as the primary solution or as the core of a rock structure.

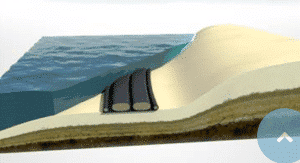

Piers

Groynes regulate the lateral movement of sand along beaches, reducing erosion and retaining sand in specific locations. Solmax Geotubes® are widely used as a mound for this purpose, improving access to public facilities such as beaches and piers.

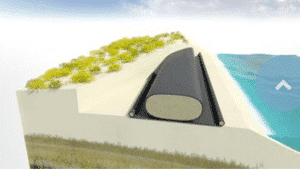

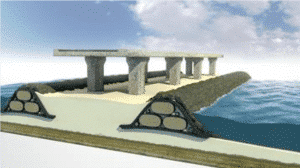

Breakwaters

Breakwaters reduce the energy of the wave before the waves reach the shore, thus reducing the erosive forces on the beach. Solmax Geotubes® are widely used worldwide for this purpose as it requires very high quality geotextiles. Here, material quality and safety go hand in hand.

Offshore structures

As a market leader, Solmax provides a comprehensive range of marine geotextiles and Geotubes® to reduce and control erosion around offshore structures such as bridges, pipelines or wind turbines.

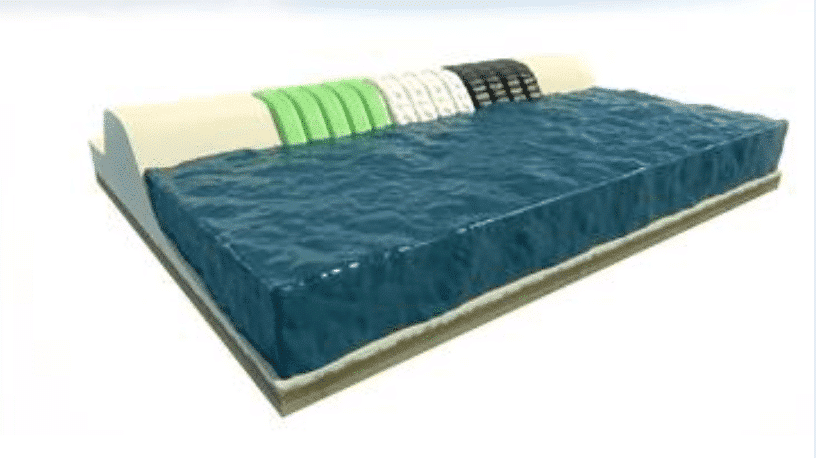

How Solmax GeoTube® works

Solmax Geotube® is used in 3 phases of coastal protection

Want to know more?

Do you need more information about Solmax Geotube® technology and how we can help you with your project?